As we’ve discussed in a previous post, hydraulic fracturing has become a repeatable process that more and more resembles a factory assembly line. The challenge, however, is to find ways to use data or oil and gas software to optimize these plays and make them profitable. As I was preparing for a presentation on complex shale lease provisions, it occurred to me that shale operations, being more closely related to manufacturing than, say, offshore operations, might benefit from applying Lean concepts.

You can read more about Lean concepts and E&P here. As the article highlights, “Lean is a process-centric improvement methodology aimed at accomplishing more with less. Lean process improvement focuses on elimination of waste and shortening production flows by benchmarking against theoretical maximum performance.”

E&P firms are inundated with data! But this data is not always available at the right time or in the right format. Successful implementation of Lean concepts necessitates looking backward and learning from history as reflected in data.

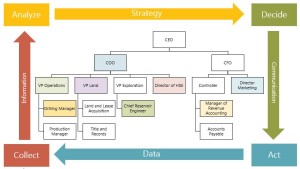

As you can see at the right, the ideal cycle for optimization of drilling involves a feedback loop that allows for constant improvements to the process.

Think about your organization and how information currently flows. Do you have tools like SharePoint and a well maintained integrated database that enables business intelligence and good decision making? Or are you relying on Excel and the contents of your inbox?

Shale is a manufacturing process that can be optimized. Don’t miss out on reaping the benefits of your own information. For more, watch our presentation to HAPL, called “Frac Your Data.”